Abstract

Consider that in a week, we can reduce specimen error by 80 percent, improving efficiency and compliance. Barcode labeling reinvented the lab as specimens could be easily identified, samples could be tracked, and bearing labels also connected with Laboratory Information Systems (LIS). Speed, accuracy, and efficiency are essential to laboratories. An effective barcode system can substantially reduce errors, facilitate regulatory compliance, and expedite results. Here, we will discuss how to configure barcode labeling in an LIS, best practices, and reasons to consider LIS integration. We’ll also demonstrate how SpeedsPath assists labs with easy specimen barcode labeling and advanced tracking.

Introduction

Laboratories process hundreds or thousands of samples daily. Each of these samples has to be properly analyzed, processed, and reported. One case of mislabeling will lead to delays, damages to patient safety, and loss of confidence in the functioning of laboratories. The remedy of the risks is through implementation of barcode labeling.

A laboratory barcode system codes every specimen with a unique code, through which the specimen could be gracefully followed through the process of collection, transportation, analysis as well as reporting. Barcode labeling works best when completely incorporated into a Laboratory Information System (LIS) that will provide real-time linking up of data, accelerated work processes and ample identification of samples.

However, it’s not as easy as printing some barcode-labeling and then pasting it onto a specimen container. For maximum efficiency, laboratories must follow barcode labeling best practices that consider design, placement, scanning accuracy, and LIS compatibility.

Importance of Barcode Labeling in a Laboratory

Other than jumping into the setup procedure, it would be worth noting the reason why barcode labeling would make such a transformation in labs:

- Accuracy and Error Reduction: There is a tendency for errors when people transcribe a document manually. Data entry errors are collapsed in an instant by the use of a barcode.

- Regulatory Compliance: Many healthcare and research regulations require that our samples have a secure system of identification.

- Quick Processing: A barcode scan is completed in a couple of seconds, as opposed to manually typing identifiers.

- Enhanced Traceability: Barcodes enable high traceability, from collection to the final report.

- Better Integration with LIS: A barcode system ensures that lab software always has updated, reliable specimen data.

Core Components of a Laboratory Barcode System

A strong Laboratory Barcode System typically consists of:

- Barcode Label Printer: This produces high quality and durable labels with high resolution and can withstand any chemical, moisture, and poor handling.

- Barcode Scanner: The device is quick enough in reading the barcodes irrespective of the type of lighting and environmental circumstances.

- Barcode Label Design Software: Enables the design of labels in terms of its type, size, layout, and information.

- LIS Barcode Integration: Ensures the barcode is linked to patient or research data in real time.

- Specimen Barcode Labeling Protocols: Defines how and when labels are generated, printed, and applied.

Step-by-Step Guide to Setting Up Barcode Labeling in LIS

Step 1: Understand Your LIS Barcode Integration Capabilities

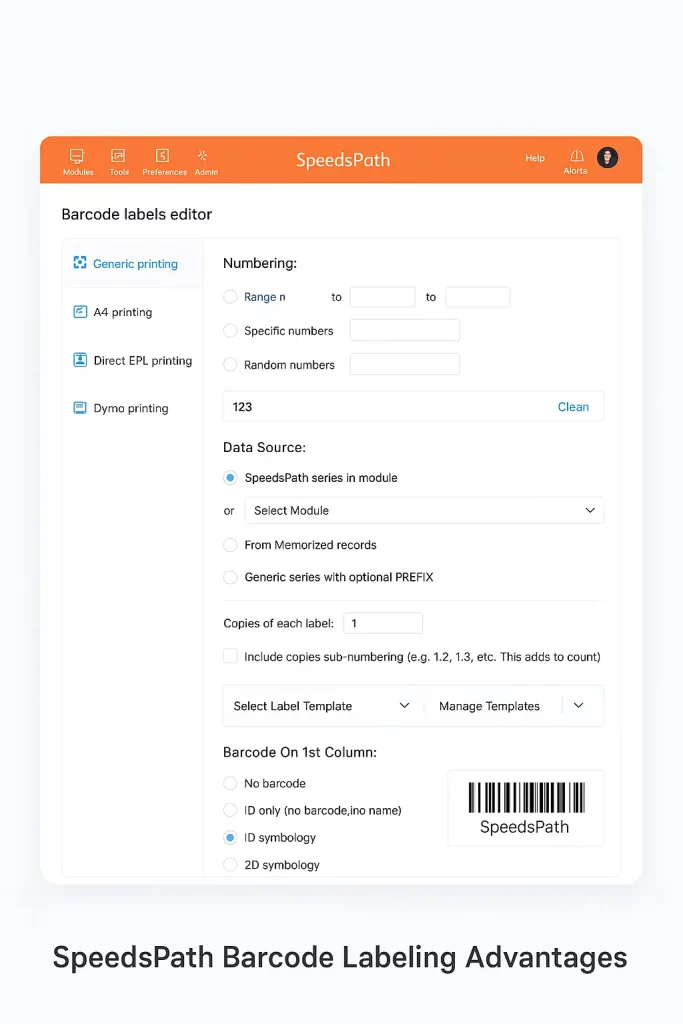

To check the capability of your existing LIS to generate and scan barcodes before implementing it. In some LIS platforms, such as SpeedsPath LIS, native barcodes are supported, so a barcode may be computer-generated and associated with a sample.

Key considerations:

- Does your LIS support 1D, 2D, or QR codes?

- Does an LIS has the capability to generate barcodes when an order is received by the lab?

- Does the barcode connect to all the metadata required (patient ID, case ID, test type, and date/time, etc.)?

Step 2: Choosing the Right Materials for Barcode Labels

- Durability of the labels depends on your working conditions in the lab. For example:

- Cryogenic samples require the use of freezer-grade labels.

- Solvent-sensitive labels are needed for chemical exposure.

- High-heat procedures require heat-resistant labels.

- Best practice: Select your materials in a way that ensures they are compatible with your lab’s workflow, allowing the barcode to be read at any time.

Step 3: Follow Barcode Labeling Best Practices

When you apply barcode labeling best practices, accuracy can be increased when scanning and fewer disturbances of workflow can be achieved.

The easiest are:

- Uniform location: Place labels in a consistent position on tubes, slides, or containers to ensure accurate identification.

- Rules out labels on other labels: labelling a document as wrinkled or turned over can interfere with the scanning.

- Font and contrasts: Font must be clear and black on a white background which is better.

- Human readable text: The human readable text will be used as a backup means when the barcodes are spoiled.

- Right size: The labels do not have to rearrange the code.

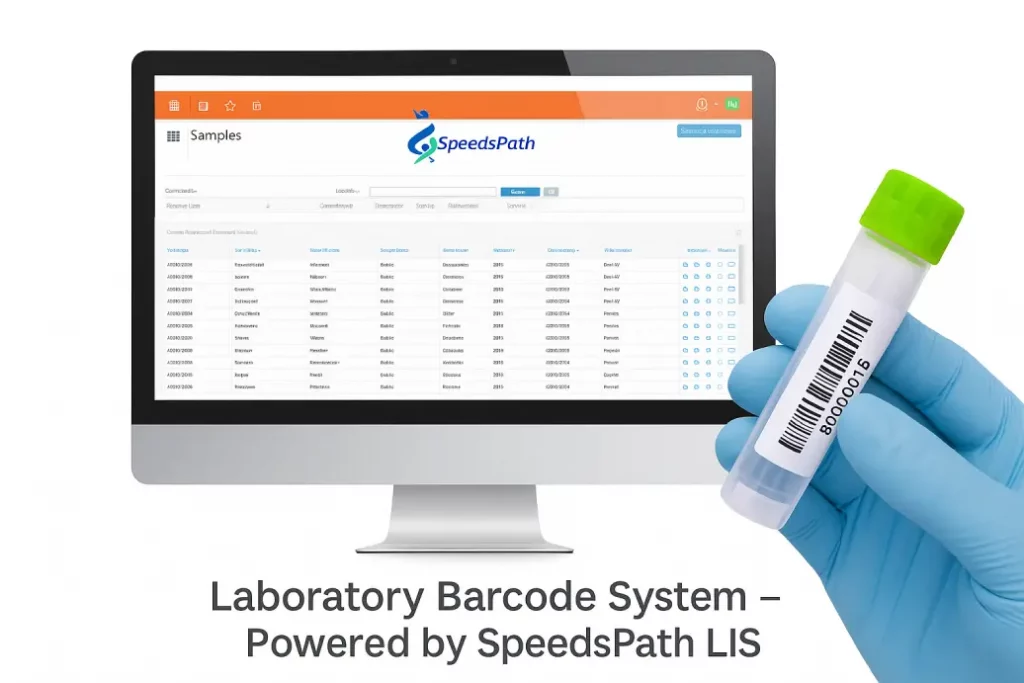

Step 4: Configure the Lab Sample Tracking System

A lab sample tracking system ensures every barcode scan updates the LIS on demand. This requires:

- LIS-connected barcode scanners.

- LIS configurations that allow scanning at the time of case data entry as well as for quick searches.

- Tracking from pre-analytical (collection) to post-analytical (report delivery) stages.

With SpeedsPath LIS, barcoding makes it easy to retrieve historical data for audits or research.

Step 5: Train Laboratory Staff

Even the most advanced system fails without proper training. Staff must be trained on:

- How to print and apply labels Correctly.

- How to scan and verify specimens.

- Troubleshooting scanner or label printing issues.

- Understanding LIS barcode workflows.

Step 6: Test, Validate, and Maintain

Prior to a full-scale implementation, test the barcode system within a series of workflows to make sure:

- Each and every barcode is scannable.

- LIS integration is seamless.

- The labeling in the lab is preserved.

Periodic maintenance involves recalibration of printers, renewal of the used-up scanners, and template upgrade of labels in order to get the best performance.

Ways of Getting Barcode Labeling Right

- Make designs simple: Simplify the information to shorten and make it specific in order to make it easier to scan.

- Select quality printers: Pick printers that print clear and sharp barcodes so that they do not delay during the process of scanning.

- Focus on staff opinion: Users should be encouraged to provide some feedback to be able to detect and solve the problems that cannot be outlined by IT groups.

- Enhance LIS integration: Ensure the lab specimen and data workflow to fully leverage the advantages of barcoding and to eliminate manual errors.

How SpeedsPath Elevates LIS Barcode Integration

At SpeedsPath, we understand that barcode labeling isn’t just a technical feature; it’s the backbone of efficient, error-free lab operations. Our SpeedsPath AP LIS offers:

- Seamless Barcode Integration: Enables generation of barcodes for each pathology specimen, order, and case.

- Flexible Label Formats: Supports various sizes, shapes, and barcode types.

- Lab Sample Tracking: Ensures every scan updates the LIS instantly.

- Specimen Barcode Labeling for All Sample Types: From blood tubes to tissue blocks, our system handles it all.

- Compliance-Ready Solutions: Meets CAP, CLIA, and other regulatory requirements.

With SpeedsPath, laboratories can confidently implement barcode labeling without worrying about data mismatches, scanning errors, or workflow bottlenecks. Our approach is designed for labs of all sizes, ranging from specialized independent and in-office pathology labs to large, multi-location facilities.

Additional Advantages of SpeedsPath Barcode Labeling Solution

Beyond integration and tracking, SpeedsPath’s barcode labeling tools are designed to enhance everyday laboratory efficiency. Our system reduces the complexity of workflows as it enables the user to print batch labels, and numerous specimen labels can be created in one mouse click, thus saving time in preparation.

Labels are applied to resist long-term durability, such as freezing, thawing, staining, and other manipulations of dried samples during experiments. Customized templates can also be created using the platform, and labs can add crucial information, including collection date, the type of specimen, and department codes, without making the platform look cluttered or unscannable.

In high-volume environments, SpeedsPath also guarantees swift print-to-application workflows, thereby eliminating bottlenecks during peak times. Combined with its ability to integrate with existing instruments and departmental modules, SpeedsPath offers a truly adaptable barcode labeling solution that grows with your lab’s needs.

Future Trends in Laboratory Barcode Systems

Barcode labeling is evolving beyond static identifiers. The next generation will see:

- 2D and QR codes that contain metadata allowing greater access to more comprehensive information.

- Tagging with RFID.

- Cloud-based tracking dashboards for remote monitoring.

- AI-powered error detection to catch mislabeling instantly.

SpeedsPath stays ahead of these trends, ensuring that your laboratory barcode system is always future-ready.

Why Choosing the Right Barcode System Partner Matters

The choice of barcode labeling system is not only a matter of technology; it is the matter of trust and flexibility as well as support over the long term. Most labs end up spending on the barcode tools later regretting the integration pains, issues concerning the compatibility of the scanners or even due to the lack of flexibility within the tools. That is why collaboration with such providers as SpeedsPath will help.

We are not just a software provider, we offer enabling technologies for the entire pathology laboratory including a barcode solution, with a set up that is matched to your workflows, type of specimen and compliance requirements. We collaborate with your team throughout the setup, training and optimization process to offer a smooth transition and short period of downtime.

With continued care, frequent software and hardware upgrades, and an approving knowledge of the LIS environment, SpeedsPath will do more than act as a vendor; it will act as a laboratory efficiency partner with you, keeping every sample, cassette, slide, and case tagged, traced, and submitted correctly.

Conclusion

Barcode labeling your LIS is not a technical upgrade: it should be a strategic decision involving greater accuracy, turnaround speed and patient and staff safety. Adherence to barcode labeling best practices, proper choice of materials, integration of the LIS barcode, and a robust lab sample tracking system will enable the laboratories to display levels of efficiency greater than any other.

With SpeedsPath AP LIS, you don’t just get a barcode feature; you get a complete solution tailored to your workflow. From specimen barcode labeling to seamless LIS integration, we empower laboratories to operate with confidence, compliance, and clarity.

FAQs: About LIS Barcode Integration

Q: What is barcode labeling in a Laboratory Information System (LIS)?

Answer: Barcode labeling in LIS assigns unique codes to each specimen, enabling accurate identification, tracking, and reporting. It reduces manual entry errors, enhances efficiency, and ensures reliable specimen management across all laboratory workflows.

Q: Why is barcode labeling important in laboratories?

Answer: Barcode labeling improves accuracy by reducing transcription errors, ensures faster processing through quick scans, enhances traceability of specimens, and helps laboratories comply with healthcare and research regulations, thereby improving both safety and efficiency.

Q: What are the best practices for implementing barcode labeling in LIS?

Answer: Best practices include using durable labels, placing them consistently, adding human-readable text, ensuring barcode-LIS compatibility, training staff on workflows, and validating systems to guarantee accurate scanning and smooth specimen tracking at every stage.

Q: How does SpeedsPath LIS improve barcode labeling?

Answer: SpeedsPath LIS offers seamless barcode integration, customizable label formats, and real-time tracking across specimens. It supports compliance requirements, minimizes errors, and provides flexible, scalable solutions for laboratories of all sizes to improve efficiency and reliability.

Q: What are future trends in laboratory barcode systems?

Answer: Future trends include using 2D and QR codes with embedded metadata, RFID-enabled tracking, AI-powered mislabeling detection, and cloud-based dashboards that provide remote specimen monitoring and real-time insights to further enhance laboratory automation.